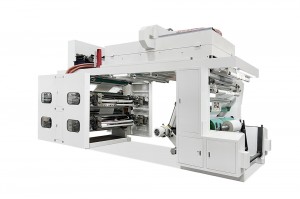

1. Qhov no ci flexographic luam ntawv xovxwm nta ib qhov txuas ntxiv, ob lub chaw nres tsheb tsis nres, tso cai rau lub tsev luam ntawv tseem ceeb txuas ntxiv ua haujlwm thaum hloov cov ntaub ntawv luam tawm lossis ua haujlwm npaj ua haujlwm. Qhov no tshem tawm tag nrho lub sij hawm nkim nres rau cov khoom hloov pauv cuam tshuam nrog cov cuab yeej siv niaj hnub, ua kom luv luv ua haujlwm thiab ua kom muaj txiaj ntsig zoo ntawm tag nrho cov khoom.

2. Ob chav chaw nres tsheb tsis tsuas yog ua kom cov khoom siv tas mus li tab sis kuj ua tiav zero cov khoom pov tseg thaum lub sij hawm splicing. Precise pre-registration thiab tsis siv neeg splicing tshem tawm cov khoom tseem ceeb thaum lub sij hawm txhua qhov pib thiab kaw, ncaj qha txo cov nqi tsim khoom.

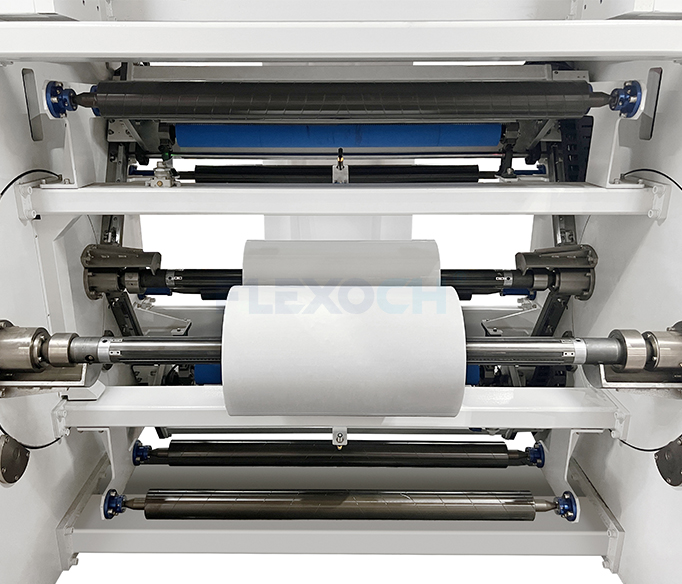

3. Lub core central impression (CI) lub tog raj kheej tsim ntawm lub tshuab luam ntawv flexographic no lav kev luam ntawv zoo. Tag nrho cov tshuab luam ntawv tau teeb tsa nyob ib ncig ntawm qhov loj, qhov tseeb qhov kub thiab txias tswj lub tog raj kheej. Lub substrate ua tib zoo ua raws li lub tog raj kheej nto thaum lub sij hawm luam ntawv, kom ntseeg tau tias tsis tshua muaj neeg sau npe raug thiab tsis sib xws nyob rau hauv cov txheej txheem ntau lawm.

4. Tsis tas li ntawd, lub tshuab luam ntawv ci flexo no tau ua kom zoo rau kev luam ntawv ntawm cov yas substrates. Nws zoo daws teeb meem xws li ncab thiab deformation ntawm cov yeeb yaj kiab yas, kom ntseeg tau tias qhov tshwj xeeb ntawm kev sau npe raug thiab ruaj khov xim luam tawm txawm tias nyob rau hauv high speeds.